Revolutionizing the Power of Centrifugal Fans: Brushless Outer Rotor Motors Usher in a New Era

Centrifugal fans are widely used in both industrial and civil fields. They play an indispensable role, ranging from ventilation and air exchange to air purification, from air conditioning systems to the treatment of industrial waste gas. As the core power component of centrifugal fans, the performance of the motor directly affects the overall performance of the fan. Traditional inner rotor motors have always been a common choice for centrifugal fans. However, with the advancement of technology, brushless outer rotor motors are gradually emerging as a superior alternative due to their unique advantages.

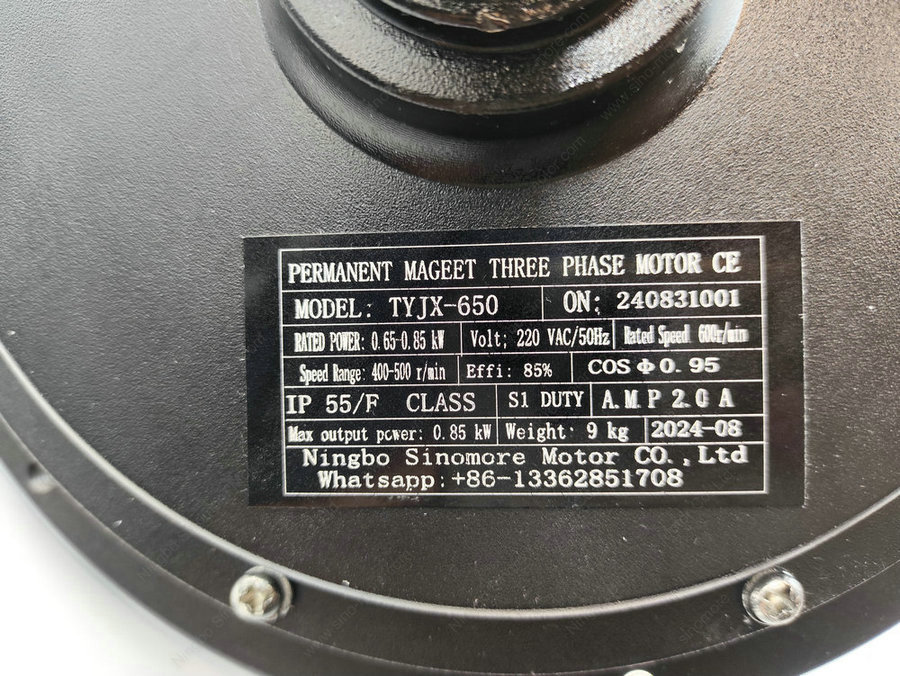

High Efficiency and Energy Conservation, Leading the Green Trend

During the operation of traditional inner rotor motors, due to structural limitations, there is a certain amount of energy loss. In contrast, brushless outer rotor motors use advanced permanent magnet materials and optimized magnetic circuit designs, which greatly improve the efficiency of the motor. Their unique outer rotor structure enables more direct torque output of the motor, reducing energy loss in the transmission process. Under the same working conditions, centrifugal fans driven by brushless outer rotor motors can achieve higher air volume and air pressure output with lower energy consumption, saving users a significant amount of electricity costs. This not only conforms to the current environmental protection concept of energy conservation and emission reduction but also reduces the operating costs of enterprises and enhances economic benefits.

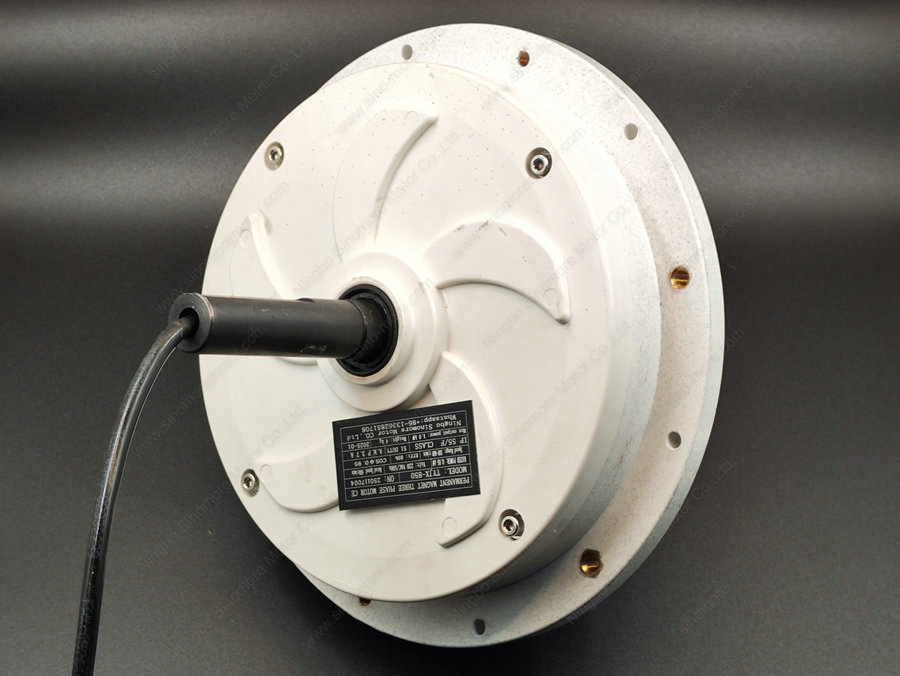

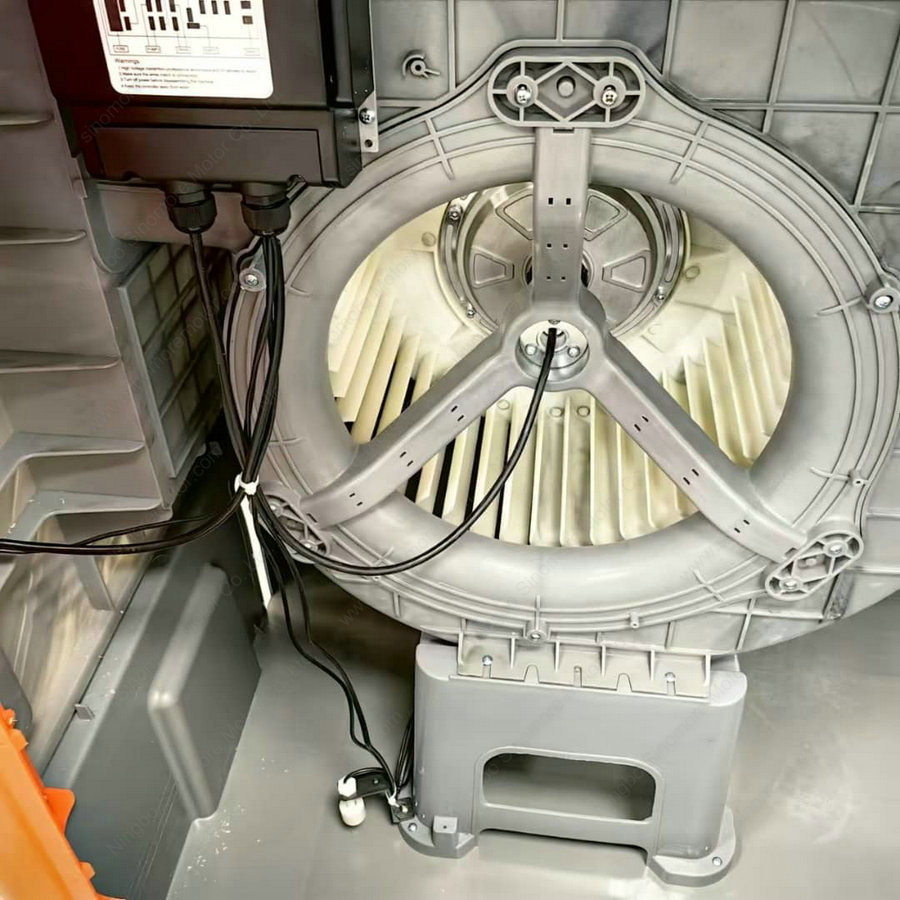

Compact and Lightweight, Optimizing Space Utilization

Traditional inner rotor motors usually need to be connected to the fan impeller through transmission components such as belts and couplings. This not only increases the complexity of the system but also occupies a large amount of space. In contrast, brushless outer rotor motors can be directly integrated with the fan impeller, combining the outer rotor of the motor with the impeller into one, making the entire fan structure more compact. This compact design not only saves installation space but also reduces the overall weight of the fan, making it easier for transportation and installation. For some application scenarios with limited space, such as the ventilation systems of commercial buildings and small industrial equipment, centrifugal fans driven by brushless outer rotor motors have obvious advantages.

Precise Control, Stable and Reliable

Brushless outer rotor motors are equipped with advanced electronic control systems, which can achieve precise control of the motor’s speed and torque. By adjusting the motor speed, the air volume and air pressure of the fan can be flexibly adjusted according to actual needs to meet the requirements of different working conditions. At the same time, the electronic control system of the brushless outer rotor motor also has protection functions such as overcurrent, overvoltage, and overheating protection, improving the reliability and stability of the motor. In comparison, traditional inner rotor motors have limited speed regulation methods and relatively low reliability, making them more prone to failures.

Low Noise and Quiet Operation, Upgrading Comfort

In some places with high requirements for noise, such as hospitals, schools, and office buildings, centrifugal fans driven by traditional inner rotor motors may generate relatively large noise, affecting the comfort of the environment. In contrast, due to the adoption of advanced electromagnetic design and optimized mechanical structure, brushless outer rotor motors greatly reduce the noise generated during operation. Their stable operation characteristics and low noise performance enable centrifugal fans driven by brushless outer rotor motors to provide users with a quieter and more comfortable environment.

Long Service Life and Maintenance-Free

Brushless outer rotor motors eliminate the traditional carbon brush structure, reducing mechanical wear and increasing the service life of the motor. At the same time, their advanced electronic control system and sealing design endow the motor with better protection performance, enabling it to adapt to various harsh working environments. In contrast, the carbon brushes of traditional inner rotor motors need to be replaced regularly, resulting in higher maintenance costs and being more prone to failures. The long service life and maintenance-free characteristics of brushless outer rotor motors save users a large amount of maintenance costs and time.

The application of brushless outer rotor motors in centrifugal fans not only brings significant performance improvements but also brings many practical benefits to users. Whether in terms of energy conservation, space utilization, control accuracy, noise control, or maintenance costs, brushless outer rotor motors have obvious advantages. With the continuous advancement of technology and the gradual reduction of costs, brushless outer rotor motors are expected to become the mainstream power choice for centrifugal fans, leading the centrifugal fan industry into a new stage of development.